Radiant Tube Heating

Radiant tube heating works really well in some environments. Its not perfect but it has its place. As an engineer, I am biased towards warm air heating as the quality of the heated space just feels better.

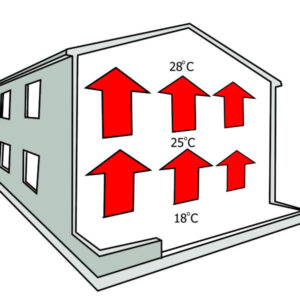

Radiant tube heaters heat the surroundings and people. Warm air does exactly that, it warms the air. Where you have a large air turn around radiant wins every time.

We have fitted radiant tube heating into a very wide range of properties over the years. We have done external wash bays, garages, loading bays to name but a few.

Radiant tubes mainly come as a single long tube (linear) or a doubled parallel tube (U tube). Generally a Gas Burner is fitted to one end of the radiant tube and a flue fan to the other.

Gas is burned directly inside the tube, the flue products are removed with a fan generally expelling outside the building. A turbulator (long spiral wound baffle) located inside the burning tube increases efficiency. Firstly it mixes (turbulate’s) the flue gasses so exposure with the tube wall is more even. Secondly is assists in slowing down the flue gasses as they pass through the tube so more heat can be used.

Radiant tube heating works by emitting electromagnetic waves. These waves travel away from the radiant tube heater and when they reach an object, they convert to heat.

Floors, benches all absorb the waves and emit heat. The space is then gradually heated as the process continues.

A Black Bulb sensor is used to calculate the workplace temperature and can connect to a majority of time / temperature controllers.

We were approached by an existing client who needed to make some urgent changes to the radiant tube heating system in their buildings.

The company was undergoing a major restructure and partial move from one building to another. With new racking fitted and a change of use the risk of hitting the radiant tube heating with fork trucks and pallets was increasing.

We moved onto site and commenced with decommissioning eight U tube heaters. Electrics were stripped out and gas feeds capped. The flue system was removed and the radiant tube heating removed from the ceiling.

Two of the best units were then retained to be fitted elsewhere.

The remainder of the radiant tube heating system was then fully serviced and Gas Safe paperwork was issued.

We began to fix all the required support steelwork into a newly formed mixing room.

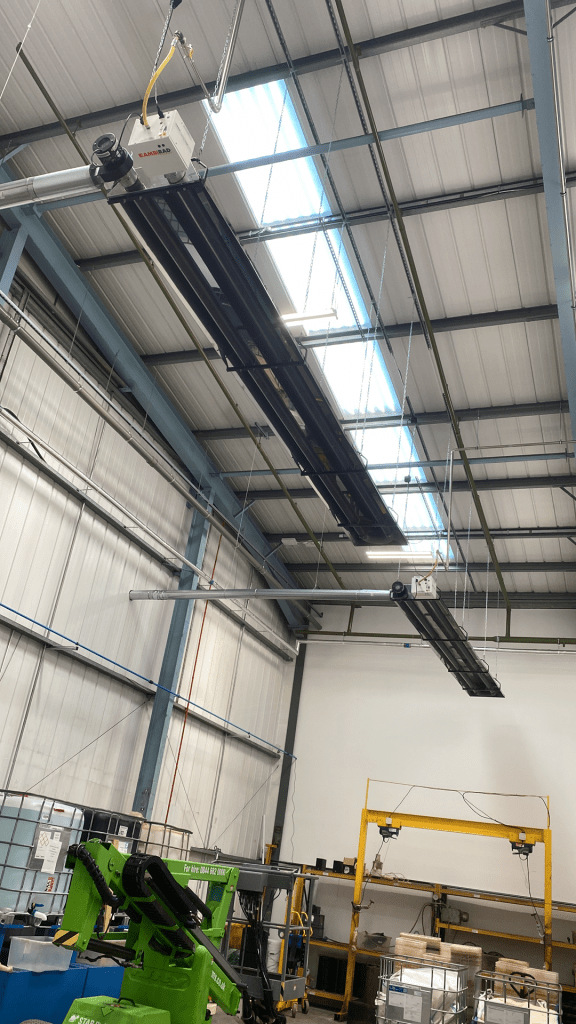

Two of the existing radiant tube heaters were cleaned and then hung from the roof.

A new gas main was installed at high level together with all electricals, black bulb sensor and time and temperature controls.

The gas supply to the building was shut down and safely locked off.

All of the old gas pipework in the building was then removed and the gas main plugged off.

The new branch for the gas was connected up, to provide gas to the radiant tube heating system.

Finally the gas main and new branch were fully tested and Gas Safe paperwork issued to the client.

We completed the flue for each heater, these were ran horizontally as the roof can not be penetrated due to lease restrictions.

Gas was connected to the heaters and safety checked.

Each of the radiant tube heaters were then turned on and fully comissioned.

Gas Safe certification was raised and given to the client.

Are you looking for a reliable commercial gas company to help you with your Radiant Tube Heating System?

We offer a wide range of services and can assist you with service, maintenance, installation and breakdown.

Please Click Here to contact us.

We prefer to supply Radiant Tube Heating Systems manufactured by Powrmatic. Why don’t you Click Here to visit the Powrmatic website?