Water Main Installation

A long-term client who owns a waste and recycling company approached us about installing a new water main. The company, situated in the West Midlands, has a zero-to-landfill strategy. Every piece of business waste that arrives at the site is recycled.

The location has a complicated recycling operation. When waste arrives at the plant, it is put into a giant shredder. The waste is crushed into little bits, which fall onto a conveyor. A network of conveyors transports waste through the production facility. Water from a water main is incorporated in case of fire.

Powerful magnets are used to recover steel and other magnetic materials. An eddy current separator is used to extract nonferrous elements such as aluminium. A network of pressurised air jets is used to remove cardboard and paper. Other materials are segregated around the plant.

All the recyclable materials that are removed are fed into various storage areas. These are stored before being later sold for recycling.

The factory is extremely efficient and processes a massive volume of waste every day. Lithium batteries provide a significant risk to the operation. Water from a water main is used for fire suppression.

In the United Kingdom, an estimated five million throwaway vapes are discarded each year. The vast majority of vapes will end up at a local waste recycling centre like this one.

When a lithium battery enters the shredder, it, like the rest of the debris in the hopper, is shredded into smaller bits.

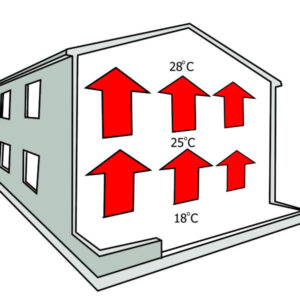

Electrolytes escape from the lithium battery when it is punctured. This generates a chemical reaction that produces heat. This heat subsequently ignites the waste around the battery.

Thermal runaway occurs and the lithium continues to burn.

A unique camera that detects fire is located above the shredder hopper. When a fire is detected, a valve is activated, and water poured into the shredder and onto the conveyor belt from a water main.

Water is utilised to dampen the waste surrounding the lithium while it continues to self-combust and burn. A conveyor modification allows the burning lithium to be channelled into a sand-filled container where it may be dealt with safely.

The initial water main setup worked, but the customer wished to boost water flow whenever a fire was detected by the camera.

We installed a DN50 (2″) water main from the incoming main through to the shredder control valve.

The water main was installed in galvanised steel.

The client also asked us to provide some take offs from this main so that hose reels could be added at the back of the shredder.

Hose reels are used all over the plant for damping down combustible material. They are also used for regular clean ups.

Our operatives installed approximately 40 metres of galvanised water main which was fitted and tested before being put into service.

A shut down was arranged and we made the final connections to the machine and water main.

During testing the huge increase of water being distributed to the shredder and conveyor deluge nozzles was immediately obvious.

The increase in water causes a lot more material to become saturated and is already proving its effectiveness when lithium batteries enter the shredder. The client is very happy with the result especially the increase in protection against fire.

The client is currently considering extending the conveyor deluge system to further increase safety from fire at the plant.

Hamer Mechanical Services are specialist pipe installers and would be happy to become involved with any water main projects you may have.

Please contact us by clicking here.

Please visit our Pipe Work Installation page by clicking here.

Interested in Industrial Shredders? Click here to read about the XR2000C used at the plant.