Remeha Gas Boiler Service

Remeha gas boiler service. This site had issues with the Remeha gas boilers just at the tail end of winter this year. One of the boilers had stopped working and the other was maintaining the full heating load. We provided the customer with a quote, they decided to wait for the summer before we carried out repairs, full strip down and service.

Need help with your Commercial Gas appliances? Hamer Mechanical Services carry out installation, maintenance and servicing work.

Click Here to visit our Commercial Gas Page.

Before servicing a gas boiler, we obtain a full spares kit from the manufacturer. Where possible, we only fit genuine OEM spare parts, essential if the boiler is under warranty.

Carrying out regular maintenance and service of a boiler is essential to maintain its efficiency and to reduce the risk of break downs during the winter months, when the boiler will be in continual use. Not only are breakdowns inconvenient, they can be almost eliminated with careful planned maintenance.

Our engineers first completely stripped down both boilers removing all outer covers, internal access panels, the burner, fan and gas assembly.

The left hand Remeha boiler had a faulty blower fan, so this was removed and disposed of.

The old ignition / ionisation probes were in terrible condition and removed and replaced.

The Remeha Quinta boiler has easily removable panels that cover the heat exchanger, giving excellent access to the combustion area for cleaning.

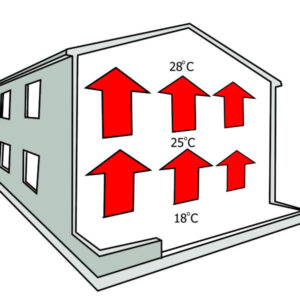

Cleaning the inside area of the combustion chamber ensures maximum heat transfer between the heat source and the water flowing inside the heat exchanger.

Keeping the boilers clean maintains the high efficiency of these Quinta boilers.

When carrying out a Remeha gas boiler service, the debris cleaned from the inside of the heat exchanger falls to the bottom of the heat exchanger. This was all removed, bagged and safely disposed of. The inside of the heat exchanger was then cleaned with compressed air and gently flushed with water. Its essential that the debris is removed, or it works into the condensate trap and begins to cause operational issues.

The Remeha Quinta boiler uses a premix burner. Gas is introduced into a stream of air which can be varied by the blower. Gas is introduced into the air stream and varies with the fan speed.

The metal gauze on the burner tube was cleaned gently using compressed air.

These burner tubes were very dirty when removed from the boiler.

The combined ignition and ionisation probe was very poor, the end of the probe was completely missing. Our engineers removed these and replaced with a brand new set.

During a Remeha gas boiler service its essential that the blower fan is removed and thoroughly cleaned. Again, a gentle stream of compressed air was used to thoroughly clean the fan assembly together with the air inlet section and gas valve.

All the seals were replaced for new when the fan was re-fitted and the air section replaced.

Once the service and repairs were carried out, the boilers were run up and re-commissioned following the Remeha OEM instructions.

The boilers flue gases were analysed and the air / gas mixture adjusted to give the correct CO2 reading on the analyser.

Gas Safe paperwork was raised and issued to the client, together with photographs of the boilers being stripped down.

Hamer Mechanical Services carries out installation, service and maintenance on a wide range of commercial gas boilers, heaters and radiant tubes.

Visit our Commercial Gas web page by clicking here.

Remeha boilers are manufactured to an extremely high quality and offer exception efficiencies.

You can visit Remeha Boilers by clicking here